Space Assets

LOCATION

Prime location in the northeastern US, close to Europe and bordering Canada with diverse transportation infrastructure, dedicated and skilled workforce, and first-class innovation and R&D centers that make Maine an excellent spot for a global 21st-century aerospace industry.

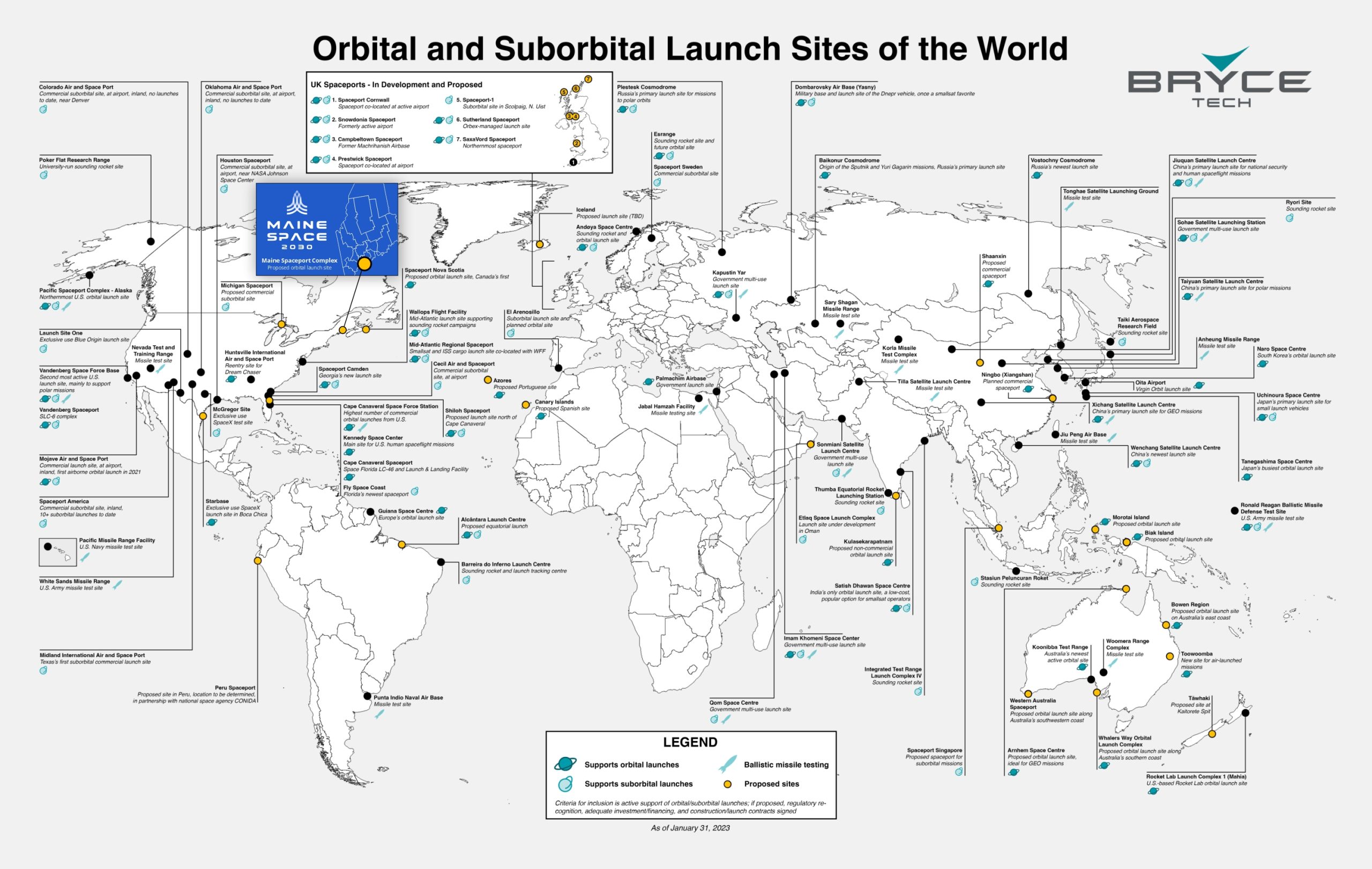

- The state’s latitude/ longitude and ample coastline offer direct and near-polar orbit access.

- Inclination between 80° and 100° from the equatorial plane for full Earth rotational coverage.

- Very low population density surrounding launch facilities.

- Potential for more eastern launches to allow either bigger payloads or higher orbit altitude if a polar orbit were not needed for full coverage of the Earth.

- Easternmost state in the U.S., Maine shares a border with Canada and is ideally placed as an international business hub, offering easy access to Montreal, Boston, New York, Hartford, and Philadelphia.

- Maine is located near the “Great circle route to Europe” from most of the United States with hubs for 5 Major US Airlines within 1-hour flight time from Maine airports.

- Proximately located within driving distance of several world-renowned research institutions.

Physical Assets

Brunswick Landing

Operated and managed by the Midcoast Regional Redevelopment Authority, is Maine’s Center for Innovation and a progressive and innovative business campus located at the former Naval Air Station Brunswick (NASB), which was decommissioned in 2011. The 3,200-acre property is equipped with state-of-the-art facilities, close to 2 million square feet of commercial and industrial space, and a world-class aviation complex that hosts hangar space, a runway, and rocket engine testing capabilities. It is also home to a small aviation and aerospace cluster on site. Brunswick Landing can meet the needs of businesses looking for a small, medium, and large industrial space, maintenance and repair facilities, and professionally appointed administrative offices. The campus includes various equipment lessees have access to and is optimized for composites and advanced materials, light manufacturing, aviation/aerospace, biotech/biomed, information technology, and renewable energy businesses. Shared manufacturing equipment includes a three-axis CNC router, 3D printer, plasma cutter, drill press, vertical & horizontal band saws, Mig Welder, and many other tools that are utilized by TechPlace tenants like a Rohner Oven (21’x15’8”x10’), Grieve Oven (4’x4’x3’), Spray Booth (24’x16’x8’8”), and Freezer (12’x12’x 8’). In just over a decade since decommissioning military operations, nearly 150 businesses and 2,600 workers now call Brunswick Landing home.

- TechPlace, Brunswick Landing’s Technology Accelerator, supports the business development needs of early-stage companies in a shared workspace. TechPlace gives entrepreneurs a place to network with others, research and develop ideas, build prototypes, test products, assemble, grow, and become successful manufacturing and technology companies. The target industries for TechPlace are Aviation / Aerospace, Biotech / Biomed, Composites and Advanced Materials, Renewable Energy, and IT.

- Brunswick Executive Airport offers two 8,000-foot runways, 650,000 square feet of hangar space and maintenance facilities, over 103 acres of taxiways and aircraft parking apron space, an advanced glycol recovery de-icing system, jet engine test and maintenance facilities, and a new instrument landing system.

- FirstLight Data Center is another asset offered at the Brunswick landing. It offers ITAR compliant data center services, carrier-grade infrastructure, light and dark fiber for data transmission, and a private, public, and/or hybrid cloud solution. It can be leveraged for use by data analytics companies for data storage on campus and low latency for advanced analytics.

Loring Commerce Centre

Home of the former site of the U.S. Air Force Base, the Centre is dedicated to economic development using the facilities of the former base. With aerospace-specific infrastructure on-site like large hangars, a runway that is the same size as Spaceport America’s at 12,000 feet by 300 feet, a turn-key data center space, fiber optic linkages to greater New England, manufacturing space, and office space, there is certainly much to offer to any company willing to work in a more remote and private environment. With a position along Maine’s fiber-optic line, low electromagnetic interference, and plenty of land available to use, perhaps the most friction-free use of Loring by the space industry could come in the form of Ground Station development and operations.

Industry and Workforce Assets

Maine is already home to a small but thriving space industry.

- Low market barriers to entry (low cost/low risk) with two preexisting launch companies – VALT Enterprises and blueshift Aerospace.

- Existing resources:

- Composite Materials R&D: layup facility, shaker tables, maker labs, etc.

- Infrastructure: former air and naval air bases in Limestone and Brunswick, available land, coastline, & airspace, aerospace-related R&D in the New England private sector and higher education institutions.

- NASA, DOD, several small and large aerospace companies, and academic institutions in the Northeast region are highly interested in using launch facilities in Maine.

- Maine is known as a composite industry R&D and manufacturing hub, anchored by the Advanced Structures and Composite Center at the University of Maine.

The aerospace industry in Maine comprises 85 companies that serve the aerospace industry exclusively or that serve the aerospace industry and other markets (non-exclusive). This collection of 85 aerospace industry participants employs ~5,000 workers.

The largest aerospace company in Maine is Raytheon subsidiary Pratt & Whitney, a Tier 1 manufacturer of jet engines and after-market service and repair in North Berwick. Pratt & Whitney employs approximately 2,100 workers in North Berwick. Another 36% of all aerospace industry companies are small to mid-sized machine shops serving multiple industries, including aerospace as tier 3 component suppliers. Maine’s companies show depth in machining and modest progress toward automated processes. Adjacent industries, such as defense and manufacturing, have capabilities transferable to the space sector and could support future industry growth. Many aerospace participant companies are not aerospace-focused but contribute to the aerospace value chain.

Launch Vehicle Systems.

Maine is home to two launch systems designers, VALT Enterprises and BluShift Aerospace, who are developing micro-launch vehicles specifically for small satellite delivery into LEO. They have been recipients of various types of US Government funding, including prestigious SBIR awards, to continue R&D on their path toward commercialization. Although still under development, they are poised to become key contributors to the space economy with a competitive advantage in environmentally sustainable solutions. VALT focuses on hypersonic delivery systems and can deploy from a vertical or horizontal launch; bluShift is vertical only.

Composite Systems & Advanced Materials.

Fiber Materials Inc. (FMI) develops and manufactures high-temperature materials and carbon-reinforced composites for industrial, commercial, and aerospace applications. FMI fabricated the thermal protection system for the Mars 2020 transport/entry aeroshell and was recently awarded a $24 million contract from NASA to provide thermal protection systems (TPS) to support several emerging missions to Mars. As a recognized leader in the manufacture of high-temperature composite materials, FMI produces components and products that serve a range of applications from industrial insulation and friction hardware and from thermal protection systems to rocket motors to nose tips. FMI materials can be found inside industrial furnaces, at the National Air and Space Museum, and on the surface of Mars. Other companies participating in the space industry include Flagsuit LLC in Southwest Harbor, which provides advanced materials and textiles for spacesuits.

Hardware Componentry.

mWAVE, a medium-sized company, specializes in custom antennas used on satellites, bringing capabilities across many radio frequencies like KA bands, KU bands, X bands, U bands across many applications. Several companies specializing in ground stations and satellite management and control services have also expressed interest in establishing operations in Maine, building upon our legacy as home to the ground station for Telstar, the first US communications satellite launched in 1962. Not only does Maine have a legacy in space, but it also has the potential to thrive and grow with the industry as it expands in the future. With its component and chip focus, Texas Instruments contributes to the new space economy and has a presence in South Portland. VX Corp, a Kyocera subsidiary in Biddeford, is a global manufacturer of advanced electronic components including antennas. Comnav Engineering produces microwave filters for wireless communication and navigation systems in Portland. Last on the list is Garmin in Yarmouth, provides downstream global positioning data and devices to the consumer market. Cascon Inc is a custom componentry developer in Yarmouth, specializing in pumps.

Machining Services.

Kennebec Technologies is a machining shop in Augusta. Southern Maine Specialties provides anodizing, electroplating, and metal finishing technologies. Hunting Dearborn provides drilling, boring, and other machining services in Fryeburg. Northwood Machine is a CNC machining shop in Thorndike. PTE Precision Machining is a full-service machining shop in Kittery. Numberall Stamp and Tool Company provides metal marking equipment for industries, primarily stamps that engrave serial, part numbers, etc., in Sangerville. Thermoformed Plastics of New England is a custom thermoforming company that offers complete design, prototyping, tooling, and production services in Biddeford.

Professional & Technical Services.

Hanna Consultants uses analytics to assist with dispersion analyses in Kennebunkport. Maine Aerospace Consulting provides industry-relevant engineering consulting in Falmouth. Greisen Aerospace provides advanced lift, craning, and loading/staging services in Brunswick.